Choose our products

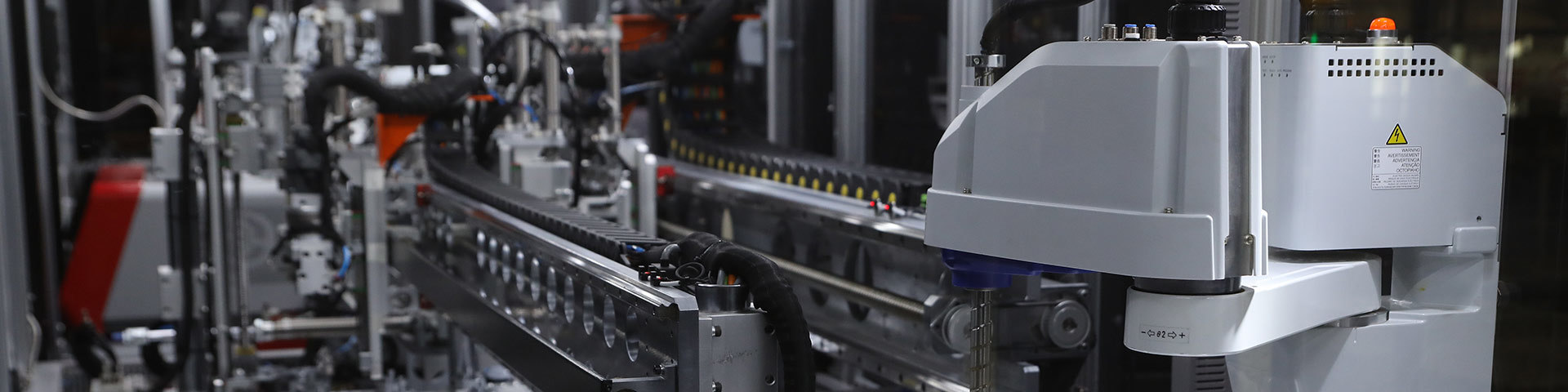

Maximum Working Pressure: 315bar

Maximum Flow Rate: 42L/min (Nominal Diameter 6)

Maximum Flow Rate: 75L/min (Nominal Diameter 10)

Maximum Working Pressure: 315bar

Maximum Flow Rate: 42L/min (Nominal Diameter 6)

Maximum Flow Rate: 75L/min (Nominal Diameter 10)

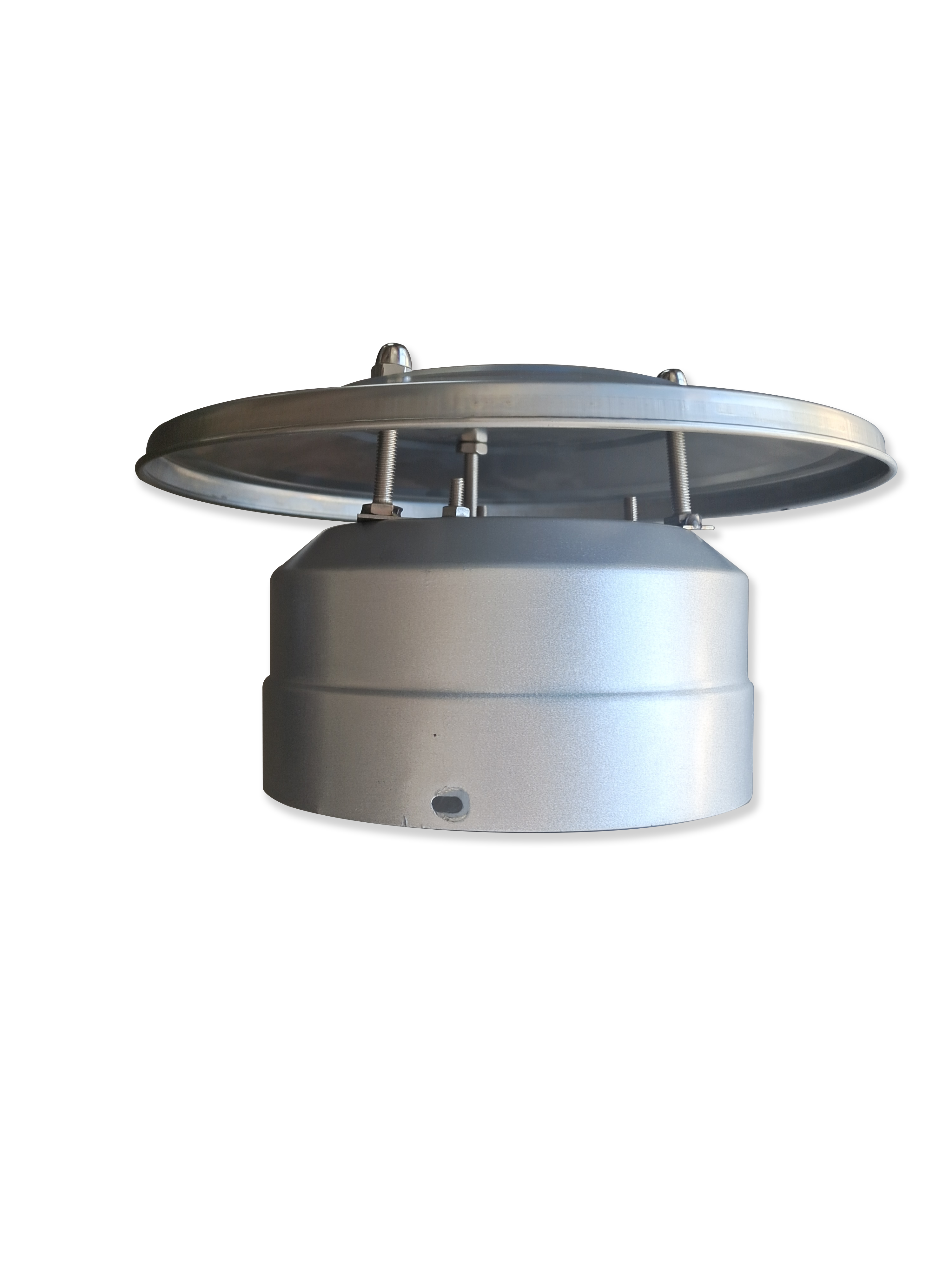

Electrically controlled machine valve group

Electrically controlled steering valve group

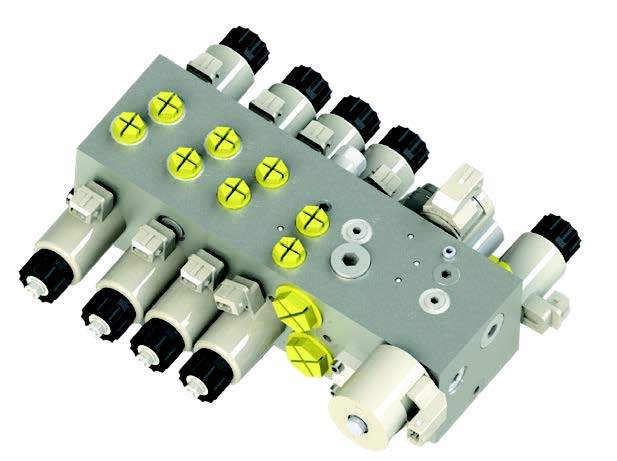

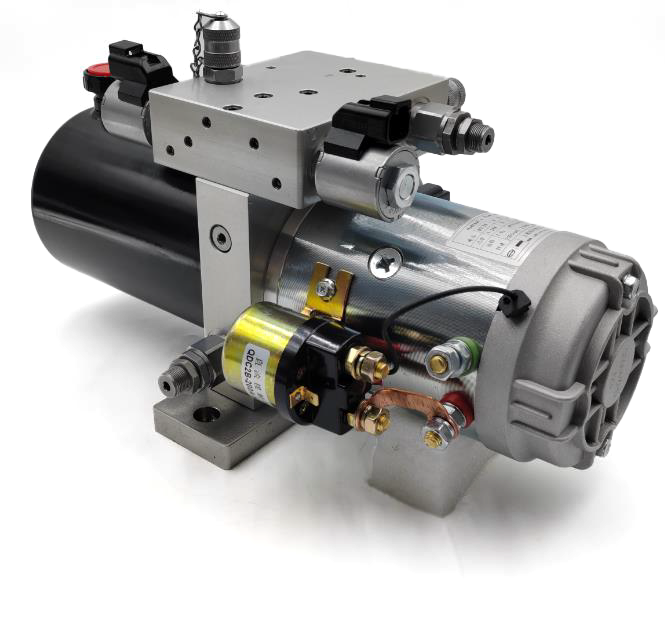

Power unit of the pallet truck

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power unit operating cycle: S2=2min, S3=7.5%ED

Before installation, ensure that the hydraulic components such as oil cylinders, oil pipes, and connectors are clean and free of impurities

During the initial startup, immediately check if the oil level in the tank is sufficient

Oil cleanliness NAS 9 grade. Change the hydraulic oil after the first 100 hours of use, and then every 3000 hours

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power unit operating system: S2=, S3=

Before installation, ensure that the hydraulic components such as oil cylinders, oil pipes, and joints are clean and free of impurities

During the initial startup, immediately check if the oil level in the tank is sufficient

Oil cleanliness NAS 9 grade. Change the hydraulic oil after the first 100 hours of use, and then every 3000 hours

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power unit operating cycle: S2=2min, S3=7.5% ED

Before installation, ensure that the hydraulic components such as oil cylinders, oil pipes, and joints are clean and free of impurities

Upon initial startup, immediately check if the oil level in the tank is sufficient

Oil cleanliness NAS 9 level. Change hydraulic oil after the first 100 hours of use, and then every 3000 hours

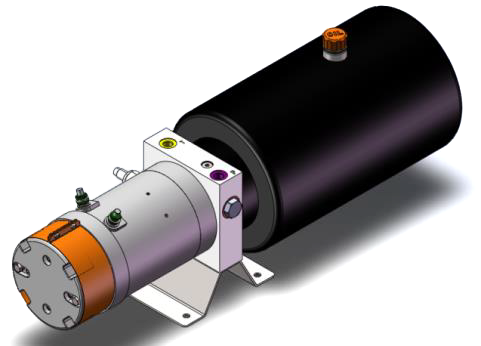

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power unit operating cycle: S1

Before installation, ensure that the hydraulic components such as oil cylinders, oil pipes, and connectors are clean and free of impurities

During the initial startup, immediately check whether the oil level in the tank is sufficient

Oil cleanliness NAS 9 grade. Replace hydraulic oil after the first 100 hours of use, and then every 3000 hours

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power unit operating cycle: S2=5min,S3=9%ED

Before installation, ensure that the hydraulic components such as oil cylinders, oil pipes, and connectors are clean and free of impurities

During the first startup, immediately check if the oil level in the tank is sufficient

Oil cleanliness NAS 9 grade. Replace hydraulic oil after the first 100 hours of use, and then every 3000 hours

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power unit operating cycle: S2=2.5min,S3=8%ED

Before installation, ensure that the hydraulic components such as oil cylinders, oil pipes, and joints are clean and free of impurities

During the first startup, immediately check whether the oil level in the tank is sufficient

Oil cleanliness NAS 9, change hydraulic oil after the first 100 hours of use, and then every 3000 hours

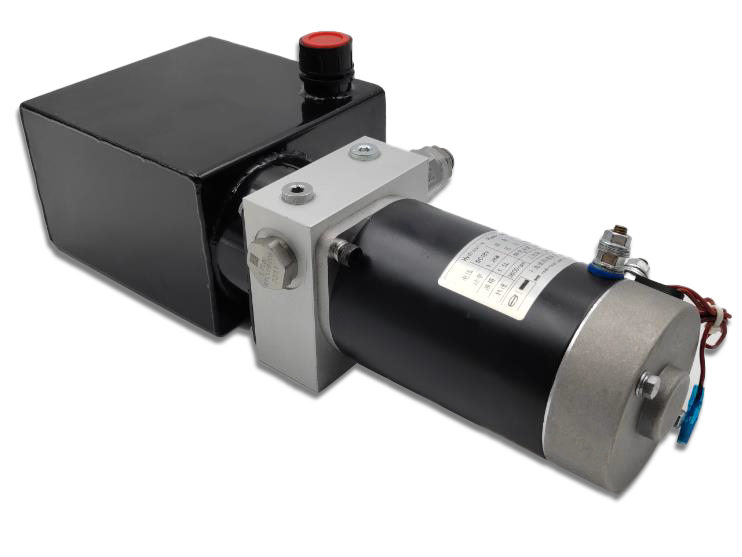

Gear pump/DC motor/Integrated circuit/Hydraulic valve/Oil tank

Power single working system: S2=3min,S3=10%ED

Before installation, ensure that the oil cylinder, oil pipes, connectors, and other hydraulic components are clean and free of impurities

During the first startup, immediately check if the oil level in the tank is sufficient

Oil cleanliness NAS 9 grade. Change the hydraulic oil after the first 100 hours of use, and then every 3000 hours